User interview – Professor Tomokazu Iyoda, Harris Science Research Institute, Doshisha University

Professor Tomokazu Iyoda is one of the world’s leading researchers in materials development, including the development of innovative permeable membranes. I was able to listen to an interesting story at the laboratory where THINKY Mixer AR-100 was recently installed.

Please tell us about your research, Professor Iyoda.

I am conducting research on the science of nano and micro materials, specifically “biotemplates” that transfer the functional structures of organic materials to other materials. In biomimetics, a field that is attracting attention, the functional structures of organisms, such as water repellency of lotus leaves, are analyzed and used for new technological development. In biotemplates, the structures of organic materials are not only reproduced but also used by transcription. Mass production of complex structures is usually difficult in industry. However, this difficulty is expected to be overcome by the use of biotemplates.

One of the microorganisms actually used for research is the microalga spirulina, which is native to Lake Chad in Africa. As the name suggests, spirulina is composed of multiple cells that are interconnected to form a helical structure, and measures 100 microns in size and 30 to 40 microns in diameter (its thickness is approximately half to one-third of that of a strand of hair). Nowadays, it is sold as a supplement and called a super food, as some of you may know. I heard that JAXA is conducting research on it for use as food for manned satellites.

Spirulina easily proliferates via photosynthesis if a sufficient amount of carbon dioxide is available. It reproduces by repeated random division into two cells. It multiplies rapidly, producing 250 identically shaped cells within approximately one week. It is the “ultimate template material” that can be easily generated under laboratory conditions. Studies of culture conditions have made it possible to control the helical pitch. Natural spirulina is left-handed, but right-handed spirulina can be produced by culture.

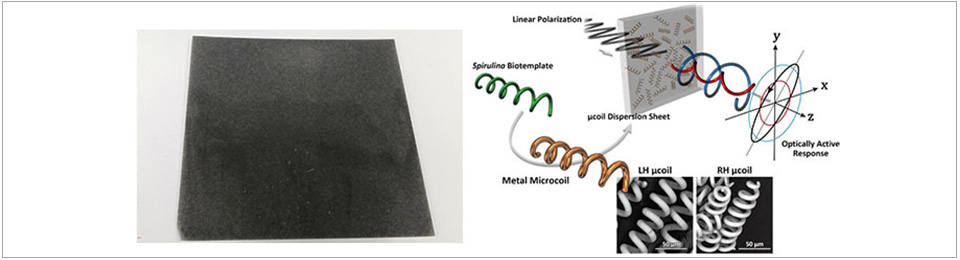

I used the helical structure of spirulina as a biotemplate to fabricate metal microcoils by the electroless plating technique. Electroless plating can plate complex-shaped objects other than metals. It had been quite difficult to perform electroless plating without changing the shape of the microorganism. It took about two years before I was able to achieve success.

First, I added spirulina into glutaraldehyde solution like into formalin. Although spirulina cells die, their helical structures are preserved by cross-linking. Electroless plating of these cells produces hundreds of millions of metal microcoils. (left photo below)

* Hundreds of millions of spirulina metal microcoils in a bottle (left) and their photomicrographs (right)

Making precision coils with wire, such as piano wire, requires much time, effort, and cost. However, the microcoils I made consist of plant and high-yield metal, and are therefore eco-friendly manufactured products.

It seems that the application of metal microcoils expands when the microcoils are mass-produced.

What will happen next?

The fact that “I made this coil” is not sufficient. The next task is to show its applications. Coils have self-resonant frequency. Small coils have high resonant frequencies. Metal microcoils made of spirulina are very small and resonate at very high frequencies. It is expected, therefore, that when electromagnetic waves, such as light or radio waves, are applied to a sheet in which the microcoils are dispersed, the microcoils inside the sheet will resonate together and absorb radio waves. I am currently working on this.

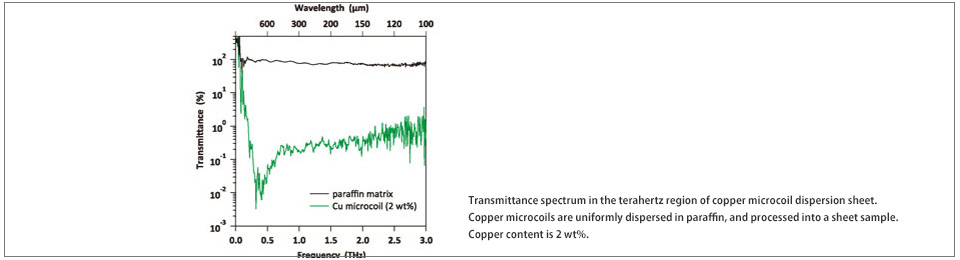

* Metal microcoil dispersion sheet (left) and schematic illustration of the research of Professor Iyoda (right)

Let me show you some examples of experimental results.

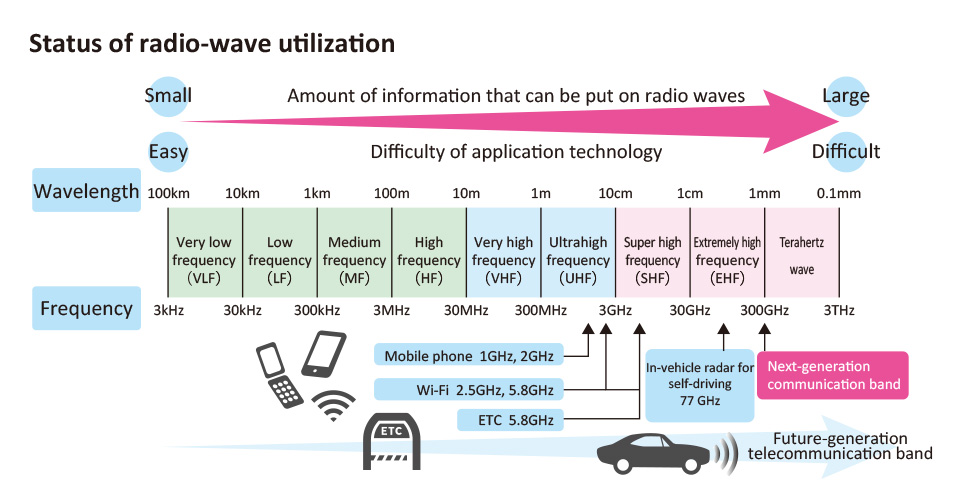

The vertical axis represents transmittance and the horizontal axis represents frequency in the terahertz region. The transmittance shows percentage leakage at the front side of the dispersion sheet for radio waves coming from behind. The figure shows that the sheet has high absorption and strong shielding function for millimeter and terahertz waves, which are considered future-generation communication bands.

By the way, the frequencies of current mobile phones are 1 GHz and 2 GHz. The ETC for expressways uses 5.8 GHz. Wi-Fi uses 2.5 GHz and 5.8 GHz. The frequency of in-vehicle radar for self-driving cars is 77 GHz by the world’s standard.

The center frequency used for future-generation communication bands is considered to be 300 GHz. In other words, it is 300 times as large as that of current mobile phones. Higher frequency means more vibrations in a shorter time and therefore more information that can be transmitted. For example, a two-hour 4K movie can be downloaded in only approximately 10 seconds. The world will change completely.

High-speed and large-capacity information communication is useful in the future, but may cause various problems. Electronic devices are vulnerable to radio waves and may malfunction. For example, hospitals have banned the use of mobile phones some time ago. Now, this restriction may be somewhat relaxed because of progress in radio-wave shielding technology. In airplanes, however, an announcement to turn off communication devices is always made for the purpose of avoiding troubles at the most important time of take-off and landing. In the future, as social infrastructure becomes wireless, there may appear various problems arising from radio-wave interference, damage on equipment caused by radio waves, etc. Its possible effects on health may become an issue as well, although details remain unknown.

It is necessary to create social infrastructure that makes the user-friendliness of radio waves and humans compatible. I believe that the demand for materials that absorb radio waves will increase.

Ferrite is famous as paint for absorbing radio waves, but it does not absorb high-frequency waves so much. It can absorb gigahertz or slightly lower frequencies but not higher frequencies, such as radar for self-driving cars. New materials with high radio-wave absorption and shielding functions will be needed for millimeter and terahertz waves that constitute future-generation communication bands. In a sheet dispersed with spirulina’s metal microcoils, free electrons in the microcoils respond to frequencies that are 10, 100, or 1000 times higher than the frequency band of ferrite. This microcoil dispersion sheet is expected to be a new material to shield the future society from flying electromagnetic waves.

How is THINKY Mixer AR-100 used in your research?

In experiments, microcoils are dispersed in an organic solvent in which plastic is dissolved, and an approximately 1-mm-thick thin film is coated on a PET film to form a sheet. In order to accurately determine radio-wave absorption characteristics, samples in which different amounts of nickel microcoils are contained in epoxy resin are prepared, and their radio-wave absorption characteristics are measured. These experiments require something like a solid panel, easy to be handled.

Because the resin to be molded has very high viscosity, I was wondering how to mix it in the laboratory. When I consulted people around me, I was told that many paint manufacturers use THINKY Mixer AR-100. I tried the equipment at a laboratory equipped with AR-100 and readily succeeded in the mixing. I immediately installed one in my laboratory. The speed is great. The microcoils can be uniformly dispersed in the resin. During the first several months after its introduction, quite a few panels have been made.

I am now working on only hard resin that is appropriate for experiments, but would like to try soft rubber and light materials, like silicone resin, as well. In the future, I am planning to produce sheets that can be easily rolled up and installed.

* THINKY Mixer AR-100 and Professor Tomokazu Iyoda.

Could you tell me about other membrane materials you are working on?

By combining hydrophilic and hydrophobic polymers that are immiscible with each other, a regular microphase-separated structure with a period of several tens of nanometers could be fabricated. Through the introduction of liquid crystallization and heat treatment, I succeeded in fabricating a membrane in which vertical cylindrical pore structures measuring 10 nm in diameter are regularly and densely arranged.

I tried various methods, such as drilling pores in polymer, drilling pores in silicone, etc. A reverse structure is also possible. When polymer is etched by adding inorganic compounds, rods are usually produced, such as silver rods, silica rods, oxide rods, polymer rods, etc. Drilling pores, making rods, etc., all of which have nanometer size, have become possible.

In conventional membranes, objects pass not vertically but through gaps where fibers are intertwined. The membranes allow objects smaller than the gaps to pass, but not larger objects. Thus, they often become clogged.

However, this membrane is completely open on both sides. Moreover, this pore vertically penetrates the membrane without branching and shows no change in diameter throughout. An object either can go in or cannot at the entrance. Once it enters, it will clearly pass through the pore, and if it cannot, it will flow sideways. The membrane is ideal because only specific targets can pass through.

Furthermore, not only am I dealing with straight objects, I am also creating a hierarchical structure just by painting, working on post-functionalization to manipulate the structure later, etc. Various relevant technologies are being developed. The structure can be changed by using a specific reagent, depending on the cation exchange membrane that is required. In other words, I am creating a universal template that is easy for users to use.

There are a lot of people who want to deal with membranes to develop applications, but it is difficult to design the appropriate membranes themselves. Membranes for testing and research are provided here. Testing is possible with them. From the trial, test membranes can be developed into those that are appropriate for the purpose. Laboratory-scale production is possible. The proof of principle has already been made, and the only thing remaining is actual production. I want to sell a lot of membranes on a roll-to-roll basis. I am looking for supporters.

Remarks after the interview

Professor Tomokazu Iyoda has an extensive background in polymer chemistry. He produced “metal microcoils” by plating chemistry by using spirulina as biotemplate. His research on radio-wave absorption by microcoils has advanced to the forefront of applied physics. He has integrated various fields with social infrastructure related issues, and there was not enough time to ask him about his enthusiasm for research, which has led to the development of tens to hundreds of new functional materials from one plus one. In the coming society of high-speed and high-capacity information communication, new materials developed by Professor Iyoda will make our lives richer. I am pleased that THINKY Mixer AR-100 plays an active role in his research. I would like to continue keeping an eye on his research in the future.

Brief biography of Professor Tomokazu Iyoda

– Research history

1984-1991 Research Associate, Department of Molecular Engineering, Graduate School of Engineering, Kyoto University

1991-1993 Researcher, Department of Chemistry, Argonne National Laboratory, USA

1994-1996 Deputy Director, JST ERATO Project: Hashimoto Light Energy Conversion Kanagawa Academy of Science and Technology

1996-2002 Professor, Department of Industrial Chemistry, Tokyo Metropolitan University

2002-2016 Professor, Chemical Resources Laboratory, Tokyo Institute of Technology

2010-2017 Director, JST ERATO Project: Iyoda Supra-Integrated Material

2016-2017 Professor, Institute of Innovative Research, Tokyo Institute of Technology (Supra-Integrated Materials Unit)

2017- Full-Time Researcher (Professor), Harris Science Research Institute, Doshisha University

– Academic Awards

1. Progress Award, The Electrochemical Society of Japan (Sano Award), 1991

2. Award for Encouragement of Research in Polymer Science, The Society of Polymer Science, Japan, 1991

3. Commendation for Science and Technology by the Minister of Education, Culture, Sports, Science and Technology (Research Division), 2007

4. The Award of The Society of Polymer Science, Japan (Science), 2009