Evaluation of materials using scanning electron microscope (SEM)

June 27, 2018|Report

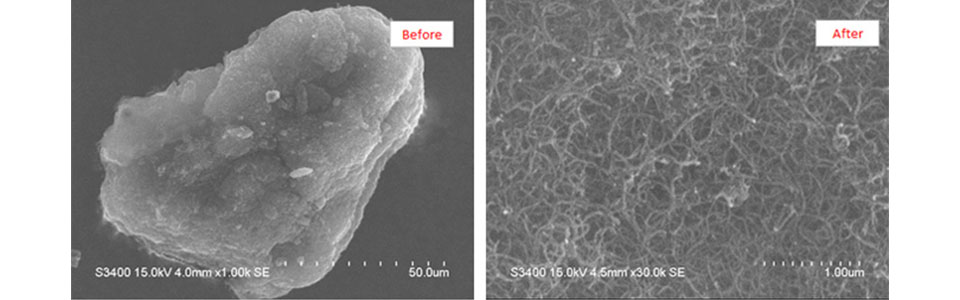

By checking the images of the sample before and after grinding and dispersion, the extent to which the sample has been ground or how it has been dispersed can be confirmed. Among several types of electron microscopes, the company uses a scanning electron microscope.

What is an electron microscope?

In conventional optical microscopes, the image of an object to be observed is magnified by light. In electron microscopes, on the other hand, it is magnified by electron beams (electrons). The electron microscopes are roughly classified into scanning electron microscopes (SEM) and transmission electron microscopes (TEM). The company uses the former, the scanning electron microscope (SEM).

Scanning electron microscope (SEM) and transmission electron microscope (TEM)

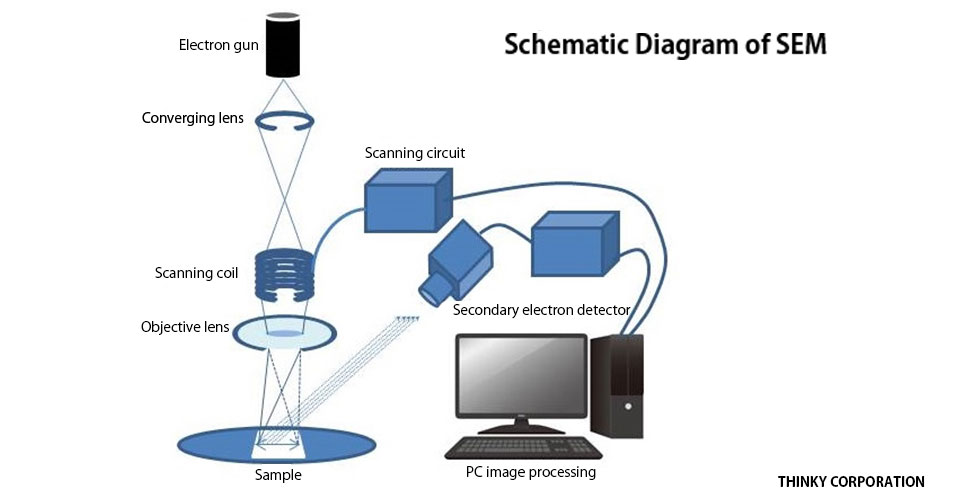

Scanning Electron Microscope: SEM

In this microscope, the image is obtained by scanning focused electron beams over the sample surface and detecting reflected electrons. It exhibits excellent ability in the observation of the internal structure close to the surface by observing the surface roughness and also making use of secondary electrons. However, a magnification (resolution) as high as that of the TEM is not possible because of the spread of the electron beam. Furthermore, the information to be obtained is limited to that near the sample surface.

Transmission Electron Microscope: TEM

In this microscope, the image is obtained by projecting electrons transmitted through the sample onto a fluorescent screen or a CCD camera. Because transmitted electrons are used, there is the advantage that information on the structure inside the sample can be obtained and higher resolution can be achieved. However, it is necessary to make the sample thinner, realize higher voltage, and achieve a higher vacuum in order to enable the electron beam to transmit through the sample. As a result, the equipment itself becomes more expensive and much larger than that of SEM.

Confirmation of state of grinding and dispersion using scanning electron microscope (SEM)

The progress in grinding and dispersion can be ascertained by checking the image of raw materials before and after processing.

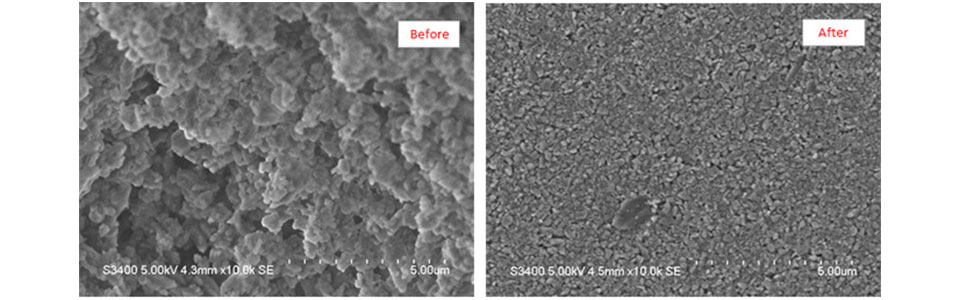

Case (1) Alumina: Grinding with NP-100

Observation of alumina ground with NP-100

SEM makes it possible to check the particle shape, etc., which cannot be determined through comparison with the results obtained using the laser diffraction particle-size analyzer (company’s equipment) or by particle-size distribution measurement. Samples to be observed with SEM must be dry. Therefore, the samples after wet grinding are observed in a dry coagulated state.

[Reference] “Evaluation method of particle size of ground material using particle size distribution analyzer”

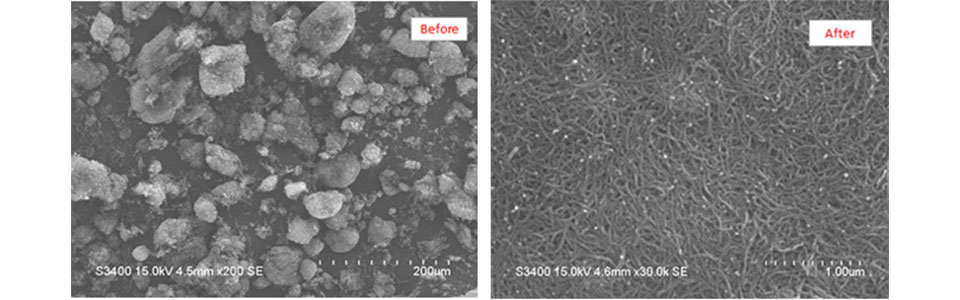

Case (2) Carbon nanotube (CNT): Dispersed with PR-1

The observation of carbon nanotubes (CNTs) before and after dispersion with PR-1.

The CNTs used are NC7000 (Nanocyl?) and Flotube9000 (Cnano?). They have a very elongated cylindrical shape and are made of carbon. Normally, CNTs are produced in aggregated form because of intermolecular forces. It is necessary to resolve (disperse) the aggregation in order to demonstrate and make full use of the performance of CNTs. Because CNTs have the elongated shape, particle size distribution measurement is difficult. It is possible to check the state of dispersion only by observing CNTs with a SEM.

NC7000 (Nanocyl?)

Flotube9000 (Cnano?)

Measurement method in Thinky Application Lab

1) Prepare ground product slurry or dispersion.

2) If material that is not removed by drying is present, remove it by centrifugation, etc. *1

3) Drop droplets onto a metal foil

4) Remove water content (solvent) of droplets (drying) *2

5) Cut the metal foil and paste it onto the SEM sample base.

6) If the specimen has no conductivity, perform sputtering to prevent the charge-up phenomenon.

7) Observation

* 1 Materials cover the sample, preventing observation.

* 2 Dry coagulation may occur during drying.