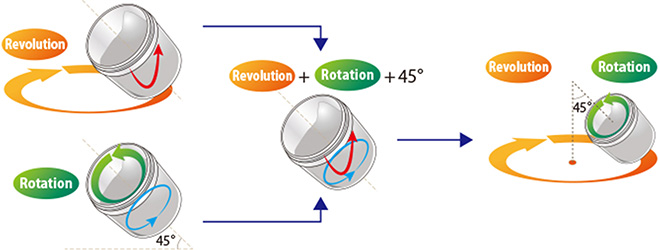

Rotation and revolution technology

-- Principles and characteristics

Reason why high-viscosity materials can be agitated without agitator blades

The planetary centrifugal mixer is a device that can agitate materials without using agitator blades and deaerate simultaneously.

There are three important factors to realize this.

(1) Revolution: Moves the material away from the center with centrifugal force.

(2) Rotation: Rotation of the container causes flow of the material (rotation and shearing).

(3) 45 degrees: Tilting the rotation axis by 45 degrees results in three-dimensional flow.

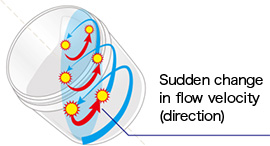

Furthermore, the flow velocity (direction) changes suddenly between the liquid surface and the container wall, causing complicated flow and strong shearing force. This shearing force makes droplets and particles smaller and increases their dispersibility. At the same time, air bubbles are also dispersed finely.

As a result, it is possible to uniformly agitate even high-viscosity materials in a short time without using agitator blades.

Reason why deaeration is possible without taking time

Difference between atmospheric-pressure type and vacuum type

Thinky's planetary centrifugal mixer consists of two types: atmospheric-pressure type and vacuum type.

In the agitation process, bubbles often cause problems, and in such a case, one of these two types can be used depending on the purpose and usage. The atmospheric-pressure type mixer can remove air bubbles of several hundred microns order, which are visible to the naked eye.

The vacuum type mixer can be used when invisible micron-sized bubbles are to be removed. Conventionally, following agitation in a mixer, deaeration is accomplished with a desiccator, etc., which takes a long time. The planetary centrifugal mixer can achieve deaeration while agitating without worrying about overflowing, greatly reducing time.

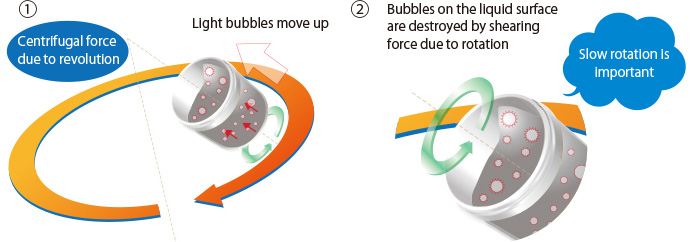

Deaeration by atmospheric-pressure type (suitable for materials with relatively low viscosity)

Most of the atmospheric-pressure type mixers are equipped with the "deaeration mode". By changing the balance between revolution speed and rotation speed, deaeration takes place on the basis of the following principles:

(1) "Centrifugal force due to revolution" forces light bubbles to the liquid surface.

(2) By applying slow rotation that engulfs no bubbles (i.e., deaeration mode), bubbles that have risen to the liquid surface are destroyed by shearing force.

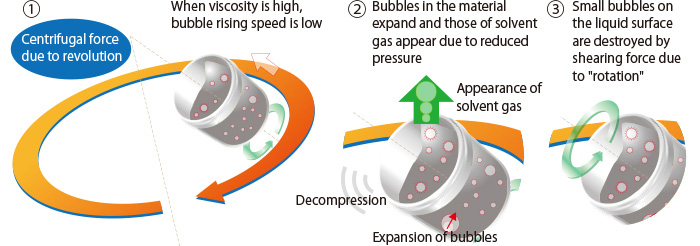

Vacuum type defoaming (suitable for materials with relatively high viscosity)

Defoaming takes place on the basis of the following principles:

1. When viscosity is high, bubble rising speed is low, and bubbles are carried to the surface by convection of the material.

2. Bubbles expand due to reduced pressure and are destroyed. Solvent gas bubbles also appear.

3. Small bubbles are also destroyed on the liquid surface by shearing force due to "rotation".

About agitation For clay mixing video