Do you like metal-based paste? | About most frequently read web pages of `Case Studies’

April 26, 2017|Topic

* This article has been distributed as a Japanese e-mail magazine in the past. The content is the same as at that time.

What subjects are the customers visiting THINKY’s website interested in? We examined which article has been popular on the search history of the “Case Studies” pages of the THINKY website.

The following was found to be the most frequently accessed article:

“Realization of time savings, quality improvement, blank shot resolution, and yield increase! ? Metal filler and various resins were uniformly dispersed merely by mixing for 30 seconds”

In addition, case studies of printed circuit boards have ranked higher, indicating that the topic of metal-based paste has been attracting much attention.

In addition to the number of times of web access, many people inquired about mixing and defoaming of metal-based paste, such as silver paste, at various exhibitions and promotional events, etc.

Metal-based paste is used as conductive paste in the field of electronic circuits and semiconductor devices. To improve its conductivity, it is important that the metal used for electric conduction is uniformly dispersed in the binder and also that the paste contains no bubbles.

Metal-based paste, such as silver paste, is often dispensed using syringes, requiring highly accurate defoaming. However, too much centrifugal force is likely to cause sedimentation. Therefore, it is difficult to stabilize the material in the well-dispersed state.

For syringe defoaming of low-viscosity conductive paste, the use of a vacuum-type mixer exhibiting a good dispersion performance is recommended. In recent years, the use of silver, gold, and platinum pastes has become more common than before in the field of high technology. The demand seems to be increasing also as a result of the requirement of using expensive materials with high yield and without loss.

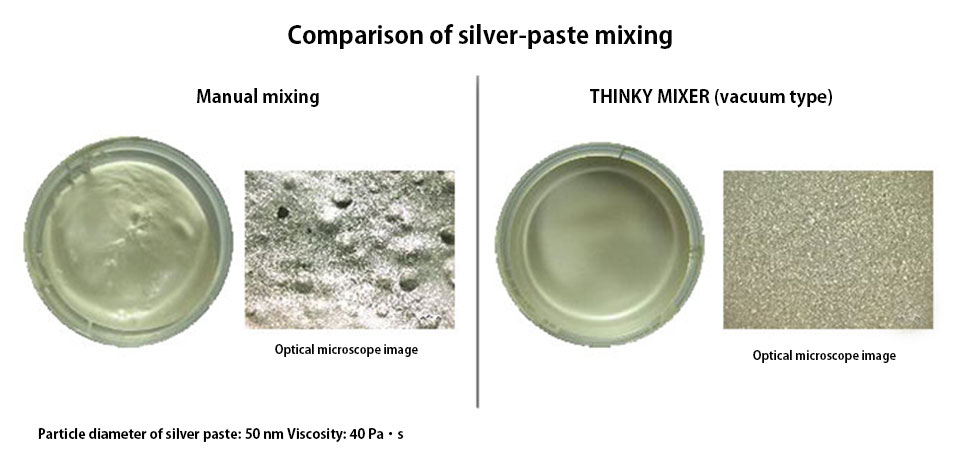

The above images show silver paste mixed by hand and that mixed using THINKY MIXER. On the left-hand side, the paste obtained by manual mixing clearly contains bubbles. The precipitated and separated paste will not be perfect even after redispersion. This paste will lead to defective items because of the blank shot of air when being discharged by a dispenser. The task of manual mixing followed by vacuum defoaming takes more than one hour. On the other hand, mixing and defoaming are completed in a mere 30 seconds by using THINKY MIXER (vacuum type). Furthermore, defoaming after transfer to a syringe is completed in a few minutes. The finished paste looks very smooth, as shown in the optical microscope image.

If you are interested in THINKY MIXER, please do not hesitate to contact us.